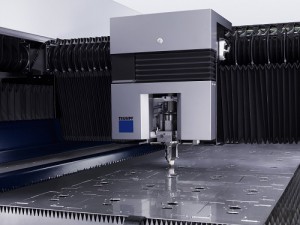

UK LASER CUTTING SERVICES

UK BASED

What is Compressed Air Cutting?

As assist gases, oxygen and nitrogen work in opposite directions. The thicker the material, the less oxygen is needed to cut it. The thicker the material, the more nitrogen is required. A third assist gas is compressed air which is much faster and cheaper for cutting steel of up to 2mm thickness. See the difference in these two cutting speed comparisons:

Oxygen cutting mild steel / Air cutting

| 1mm | 1.3mm | 1.5mm | 2.0mm | |

| Oxygen | 7.5 | 7.0 | 6.7 | 5.5 metres/min |

| Air | 13.5 | 10.0 | 7.4 | 5.6 metres/min |

Nitrogen cutting / Air cutting

| 1mm | 1.3mm | 1.5mm | 2.0mm | |

| Nitrogen | 8.2 | 7.7 | 7.0 | 5.0 metres/min |

| Air | 16.0 | 10.8 | 7.5 | 6.6 metres/min |

The benefit of faster cutting times means the manufacturing cost per component will be less than ordinary laser cutting with oxygen or nitrogen.

The standard assist gases, oxygen and nitrogen, create two reactions in laser cutting. Oxygen creates an exothermic reaction, burning the metal in a fashion similar to CNC flame cutting. Nitrogen cutting, on the other hand, uses a sublimation, or melting, technique. The process heats the metal without a chemical reaction, and the high pressure of the nitrogen gas pushes the resulting molten puddle through the kerf.

During air cutting, the reaction produces plasma. This is similar to the way in which a CNC plasma cutting center uses electricity to create plasma. Laser energy is brought to a tight focal position, and the introduction of compressed air creates a plasma ball at the surface of the material.

Plasma transfers heat more effectively than the laser beam does by itself. In fact, increasing the cutting speed often is necessary to prevent over-melting the material edge. Sometimes this edge melting can cause confusion, as operators may think they are cutting too fast when they are actually cutting too slowly.

0115 9269649

0115 9269649 Email Us

Email Us Contact Us

Contact Us